Summary

Skills:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Project Background

Automatic ball launchers in sports, like soccer, often lack efficiency due to manual adjustments, inability to target moving players, and imprecise measurements. To address these issues, our team of 6 engineers developed KickPro, featuring a camera-based human tracking system for real-time player tracking and automatic launcher adjustment.

Contributions

In 8 months, our team underwent a full development cycle, from brainstorming to market-ready product. As Chief Branding Officer, my role encompassed market research, mechanical design, and electronics design.

Mechanical Design and Assembly

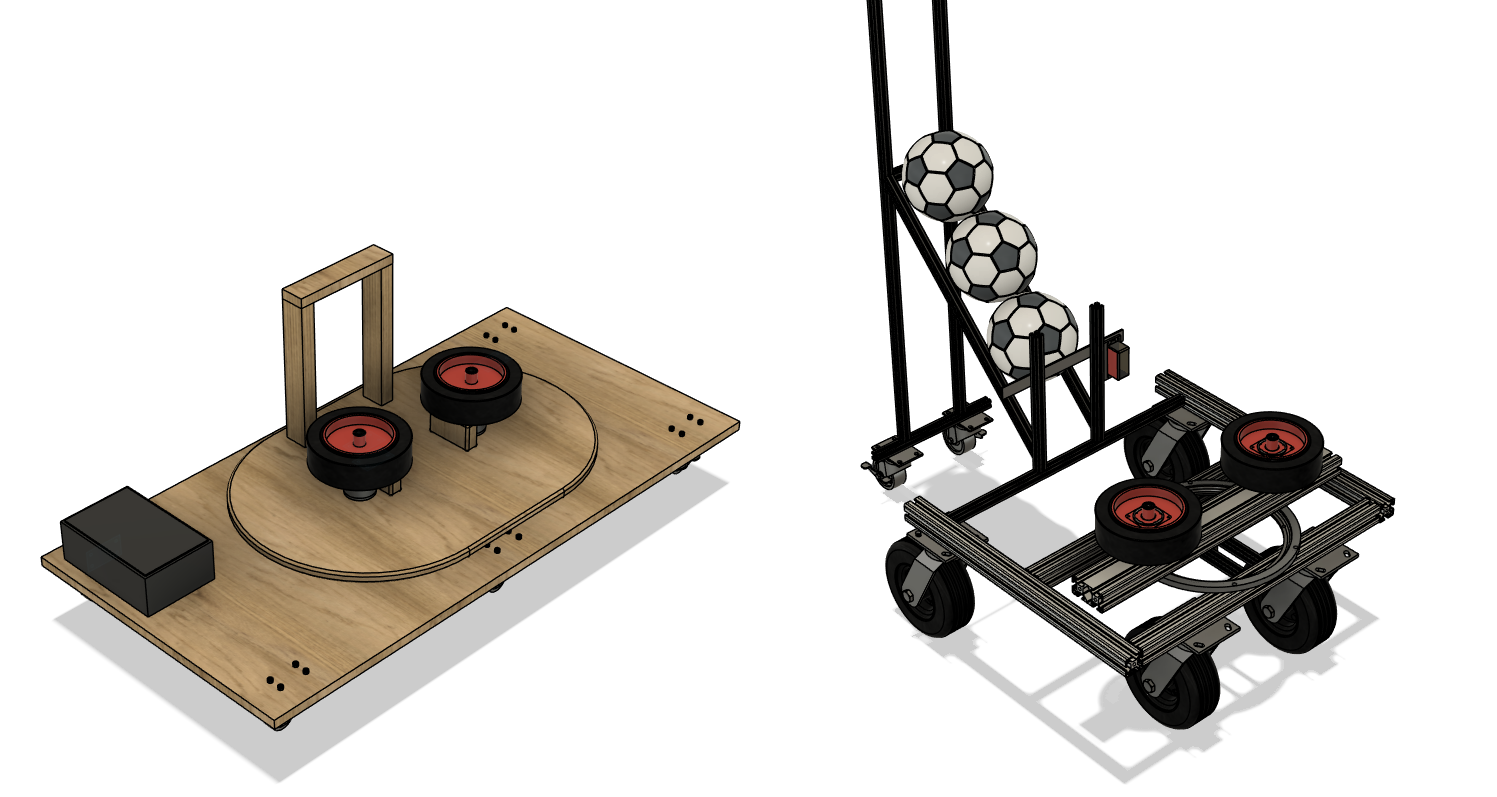

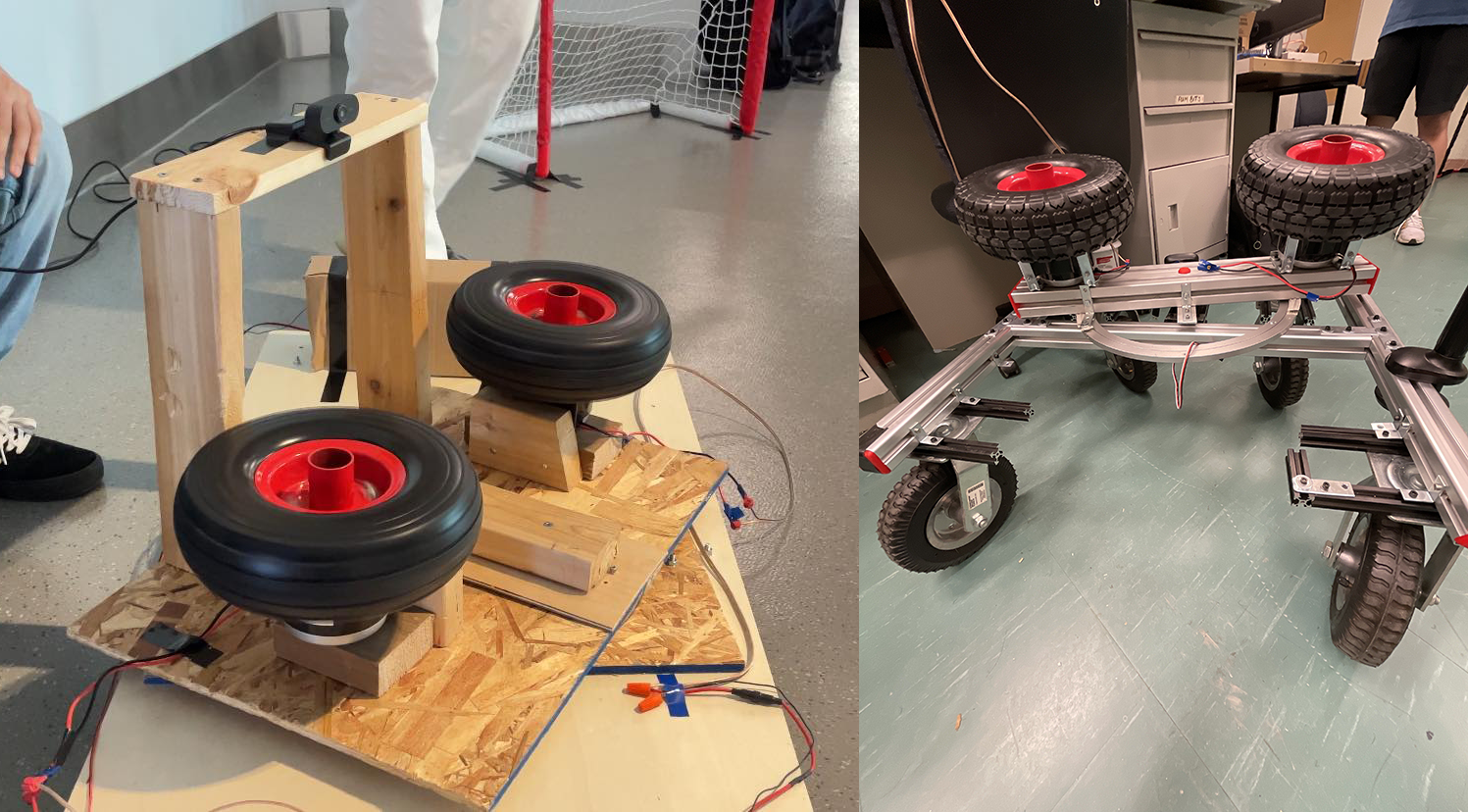

As a mechanical engineer, I designed, developed, and assembled the mechanical structure of both the prototype and the final product. Utilizing Fusion 360, I designed the initial prototype with a swivel mechanism, flywheel for launching, and basic castor wheels for mobility. However, structural instability due to the high inertia of DC flywheel motors led to a complete redesign. The final product incorporated a sturdy frame using aluminum extrusions, resolving vibration issues caused by motors. Pneumatic wheels replaced castor wheels, ensuring stability even at high flywheel speeds and enabling mobility on various surfaces.

Old Prototype (Left) vs. Final Product (Right) - CAD Models

Old Prototype (Left) vs. Final Product (Right)

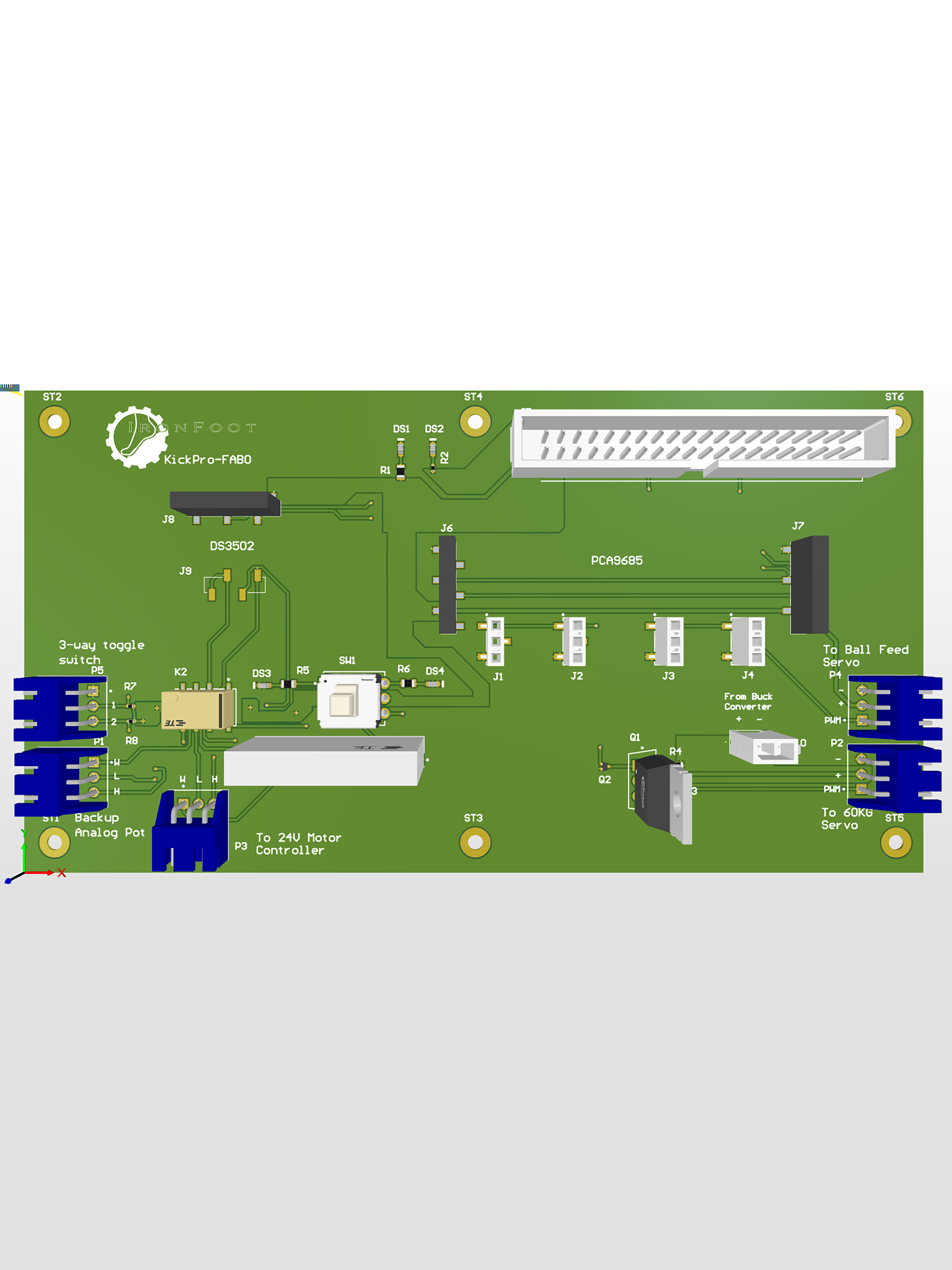

Electronics

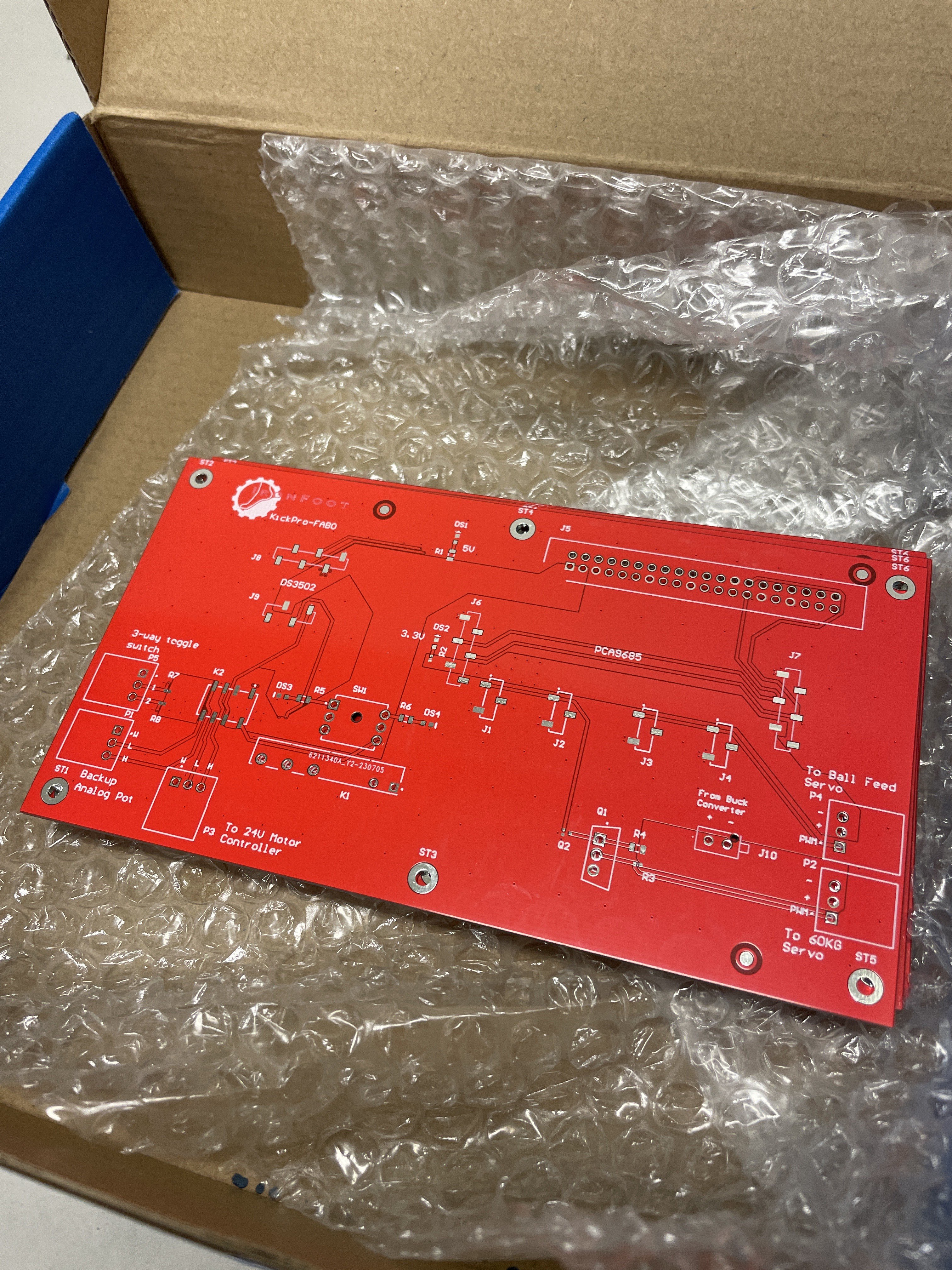

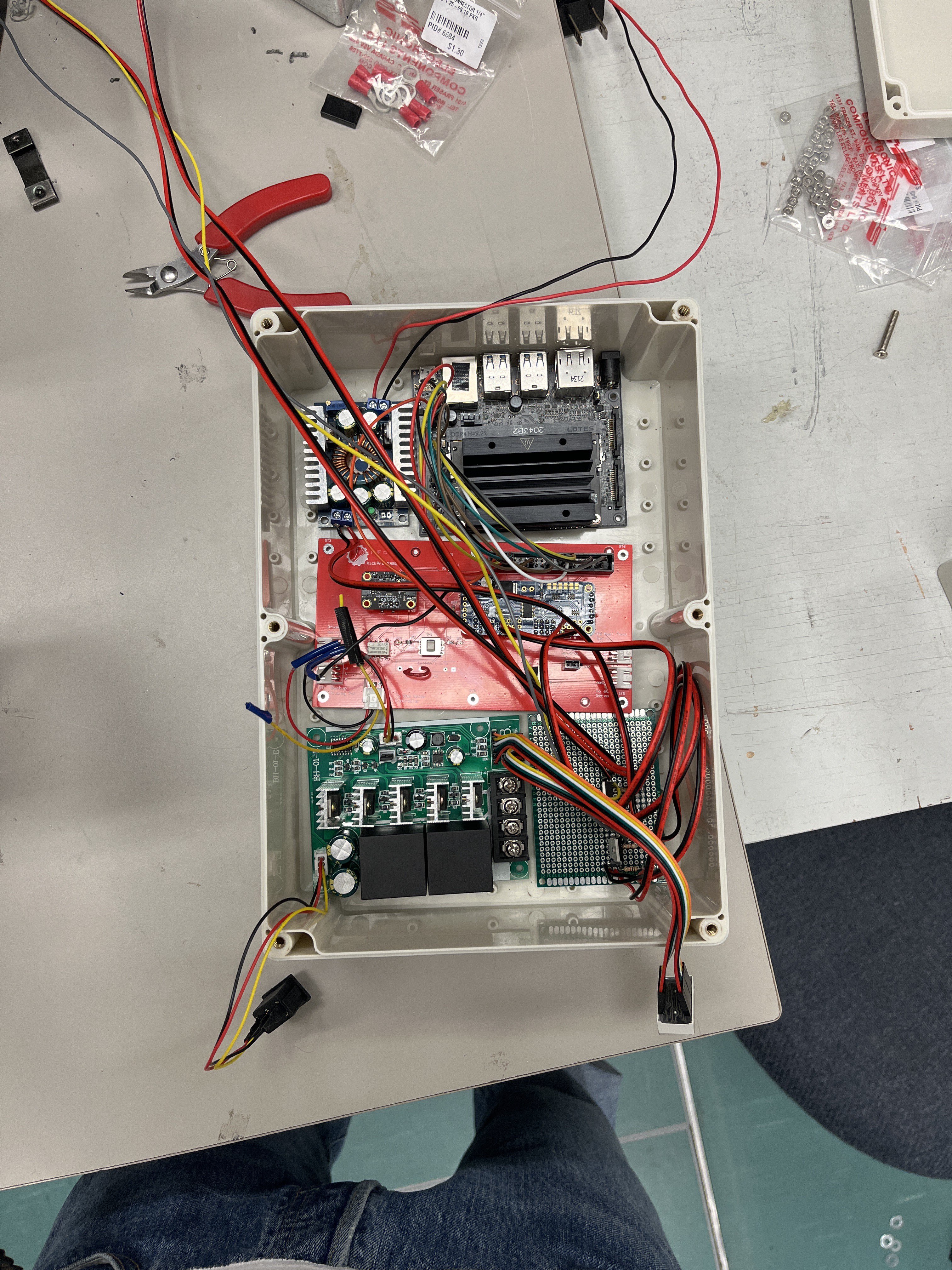

As a member of the electronics team, I played a key role in crafting the project's electrical foundation. I contributed to circuit design, breadboarding, and PCB development. My responsibilities included researching and selecting appropriate electrical components, creating a prototype circuit on a breadboard, and developing a schematic library and circuit schematic in Altium Designer. The finalized PCB, derived from our schematics, was ordered through a manufacturing company and subsequently assembled by myself and fellow team members.

Altium PCB CAD Model

Pre-Soldered PCBs

Complete Electronics Assembly

Video Demo

The device shown is the first prototype created within the first 4 months of the development process, demonstrating the human tracking ability of KickPro.

Here is a clip of the final product dispensing and launching the ball at the player during the testing of the ball feeding mechanism.